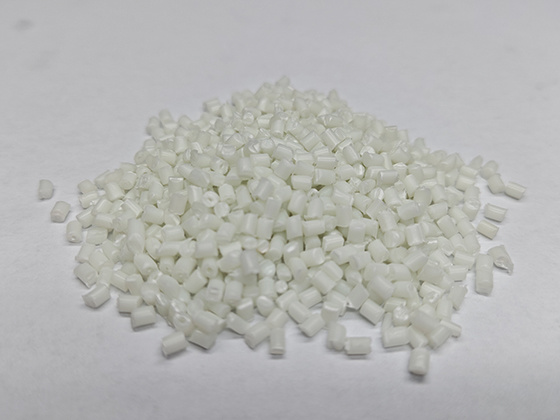

Modified PBT

Classification:

Product Introduction

Product Details

Modified PBT

| Enhanced and toughened PBT | |

| Natural toughened PBT+GF10 | W31G10NC01 |

| Natural toughened PBT+GF15 | W31G15 |

| Natural toughened PBT+GF20 | W31G20 |

| Natural toughened PBT+GF30 | W31G30 |

| Flame retardant PBT | |

| White bromine-based V0 flame retardant PBT | W31NWT15 |

| Reinforced flame retardant PBT | |

| Gray bromine-based V0 flame retardant reinforced PBT | W31G20NGY16 |

| Black bromine-based V0 flame retardant reinforced PBT | W31G30NB07 |

Enhanced and toughened PBT

Product introduction: Glass fiber reinforced toughened modified PBT. This type of product is mainly used in automotive parts and connectors, high-end electronic appliances, home appliances, consumer electronics, industrial equipment parts, etc.

Product details: Glass fiber reinforced toughened PBT, injection molding grade. The product has good balance of rigidity and toughness, excellent heat resistance, chemical resistance, electrical properties and processing properties.

| Main performance items | Unit | Test standard | Natural toughened PBT+GF10 W31G10NC01 |

Natural toughened PBT+GF15 W31G15 |

Natural toughened PBT+GF20 W31G20 |

Natural toughened PBT+GF30 W31G30 |

| Density | g/cm3 | ISO 1183 | 1.354 | 1.389 | 1.429 | 1.503 |

| Ash content | % | ISO 3451 | 10 | 15 | 20 | 30 |

| Tensile strength | MPa | ISO 527 | 79 | 98 | 106 | 131 |

| Elongation at break | % | ISO 527 | 6 | 6 | 7 | 6 |

| Flexural strength | MPa | ISO 178 | 126 | 146 | 162 | 200 |

| Flexural modulus | MPa | ISO 178 | 4077 | 4859 | 5730 | 8565 |

| Notched Izod impact strength (23℃) | KJ/m2 | ISO 180 | 12.8 | 13.8 | 14.3 | 17.2 |

| Notched Izod impact strength (-40℃) | KJ/m2 | ISO 180 | 8.1 | 8.3 | 9.2 | 13 |

| Unnotched Izod impact strength (23℃) | KJ/m2 | ISO 179 | 78 | 62 | 66 | 75 |

| Unnotched Izod impact strength (-40℃) | KJ/m2 | ISO 179 | 45 | 42 | 48 | 78 |

| Melt flow index (235℃/2.16kg) | g/10min | ISO 1133 | 8.5 | 2.5 | 2.3 | 5.5 |

| Heat deflection temperature (1.8 MPa) | ℃ | ISO 75 | 179 | 185 | 199 | 206 |

Flame retardant PBT

Product introduction: Flame retardant modified PBT. This type of product is mainly used in the new energy vehicle electronic control system, electronic and electrical connectors, photovoltaics, and home appliances industries.

Product details: Flame retardant PBT, injection molding grade, phosphorus-nitrogen halogen-free system, bromine-antimony nanometer, hyperbranched polymer modification. The product has high-grade flame retardancy, excellent electrical properties, durable processing and high fluidity.

| Main performance items | Unit | Test standard | White bromine-based V0 flame retardant PBT W31NWT15 |

| Density | g/cm3 | ISO 1183 | 1.416 |

| Ash content | % | ISO 3451 | / |

| Tensile strength | MPa | ISO 527 | 50 |

| Elongation at break | % | ISO 527 | 11 |

| Flexural strength | MPa | ISO 178 | 77 |

| Flexural modulus | MPa | ISO 178 | 2323 |

| Notched Izod impact strength (23℃) | KJ/m2 | ISO 180 | 7.9 |

| Notched Izod impact strength (-40℃) | KJ/m2 | ISO 180 | 7.5 |

| Unnotched Izod impact strength (23℃) | KJ/m2 | ISO 179 | 152 |

| Unnotched Izod impact strength (-40℃) | KJ/m2 | ISO 179 | 74 |

| Melt flow index (235℃/2.16kg) | g/10min | ISO 1133 | 19.6 |

| Heat deflection temperature (1.8 MPa) | ℃ | ISO 75 | 64 |

| Flame retardant properties | 1.6mm | UL94 | V-0 |

| 3.2mm | V-0 |

Reinforced flame retardant PBT

Product introduction: Glass fiber reinforced flame retardant modified PBT. This type of product is mainly used in new energy vehicle charging, miniaturized integrated circuits, high-voltage energy storage, and high-end electronics industries.

Product details: Glass fiber reinforced flame retardant PBT, injection molding grade. This type of product has the characteristics of high flammability, high fluidity, low warping, electrical properties and weather resistance, high glow wire, and high strength and rigidity.

| Main performance items | Unit | Test standard | Gray bromine-based V0 flame retardant reinforced PBT W31G20NGY16 |

Black bromine-based V0 flame retardant reinforced PBT W31G30NB07 |

| Density | g/cm3 | ISO 1183 | 1.578 | 1.65 |

| Ash content | % | ISO 3451 | 22 | 37 |

| Tensile strength | MPa | ISO 527 | 84 | 128 |

| Elongation at break | % | ISO 527 | 5 | 6 |

| Flexural strength | MPa | ISO 178 | 125 | 192 |

| Flexural modulus | MPa | ISO 178 | 5931 | 11135 |

| Notched Izod impact strength (23℃) | KJ/m2 | ISO 180 | 7.8 | 9.2 |

| Notched Izod impact strength (-40℃) | KJ/m2 | ISO 180 | 7.8 | 8.7 |

| Unnotched Izod impact strength (23℃) | KJ/m2 | ISO 179 | 38 | 64 |

| Unnotched Izod impact strength (-40℃) | KJ/m2 | ISO 179 | 26 | 64 |

| Melt flow index (235℃/2.16kg) | g/10min | ISO 1133 | 2.8 | 1.3 |

| Heat deflection temperature (1.8 MPa) | ℃ | ISO 75 | 160 | / |

| Flame retardant properties | 1.6mm | UL94 | - | V-0 |

| 3.2mm | V-0 | V-0 | ||

| Glow wire | ℃ | IEC 60695 | 770℃ non-flammable | 770℃ non-flammable |

Key words:

Online Message

Leave a message immediately and get the product quotation free of charge. We will arrange the specialist to contact you as soon as possible.